Questions every growing lash brand eventually asks.

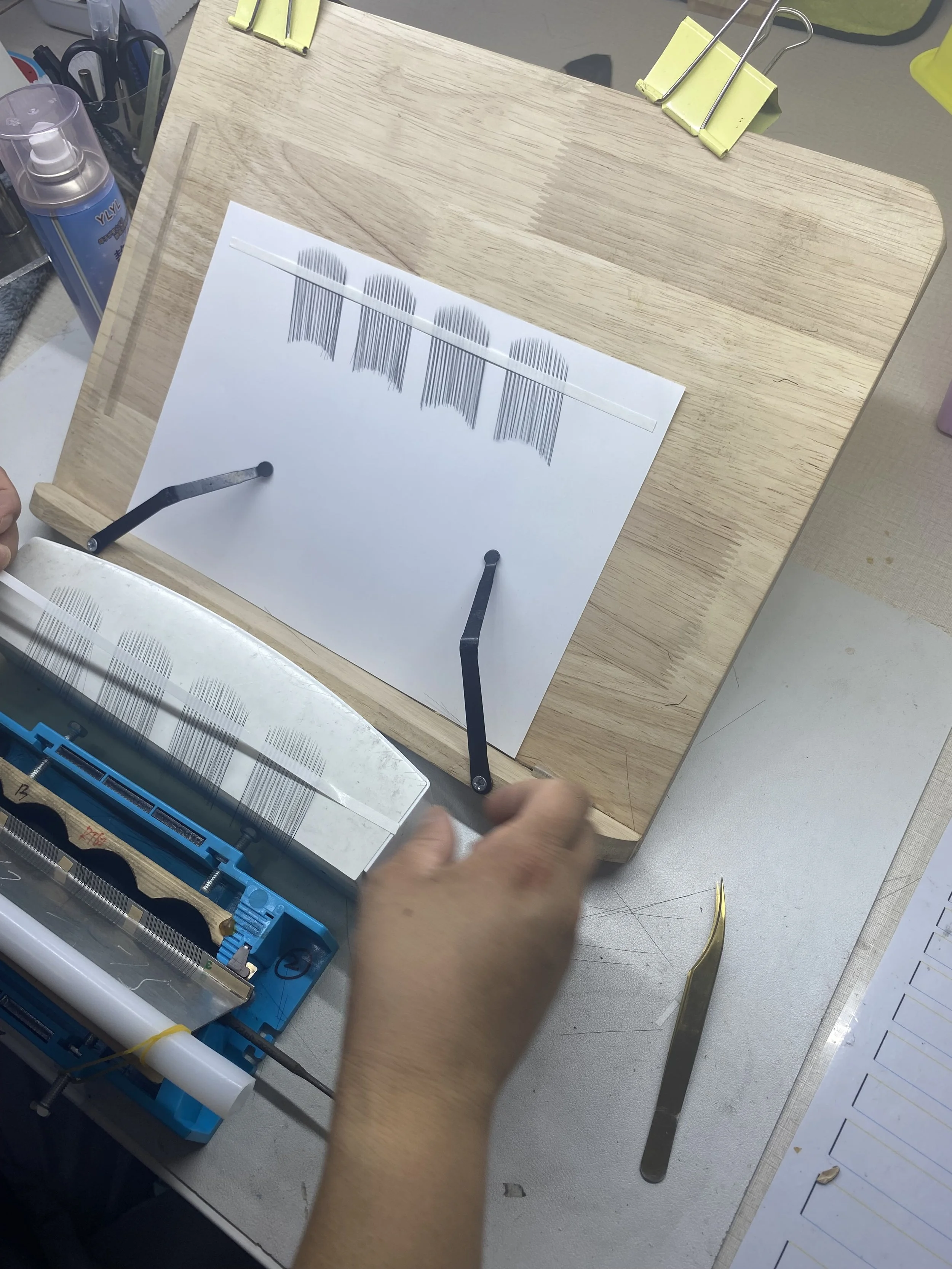

Q: What quality-control steps do you take before producing lashes?

Before we produce anything, we test the system first — not just the lash.

Handmade lashes can shift easily, so our QC starts at raw materials and continues through every production stage. We check curl tension, spacing, density, and band softness using trained staff who understand lash technique, not temporary workers.

Most factories cut corners to save cost because real QC requires staff, time, and training. We don’t move forward unless each checkpoint passes — because there’s no point producing 20,000 units if you’re not willing to invest in the people needed to keep the quality stable.

Q: Do you test lash trays and boxes for durability and fit (not just appearance)?

Yes. We test:

Tray compartment strength

Lid closure alignment

Lash protection during movement

Box structure, finish, and protective inserts

One big difference between good and average packaging manufacturers is the tray-cutting system. We use high-precision cutting so edges are clean and consistent — which prevents lashes from catching or bending inside the tray.

Q: Is your lash glue batch-tested for performance before being labeled “retail ready”?

Yes. Every glue batch is tested for:

Lot code tracking

Dry-time consistency

Viscosity stability

Seal integrity

Humidity + temperature performance

We keep reports for every glue batch we produce. This is why your glue performs the same from the first bottle to the last.

Q: Do you handle shipping, customs duties, and tariffs so I don’t get surprise costs?

Yes. Our pricing includes production, shipping, duties, and tariffs.

You receive a full landed-cost quote before placing your order.

No hidden fees. No surprise bills. No math on your end.

Q: Can you ship to multiple retail locations (boutiques, warehouses, distribution centers)?

Yes. We can split shipments, coordinate delivery timelines, and prepare location-specific labeling. This makes multi-store launches simple and prevents you from becoming a logistics manager while your brand is growing.

Q: Will the same lash batch remain consistent if I reorder after 6–12 months?

Yes — with the natural tolerance that comes with handmade production.

We lock your specs into a Master Production Template, so your curl, spacing, density, and band softness remain stable across reorders — even years later.

95% consistency in handmade lashes is already considered excellent, and our system maintains that standard reliably.

Q: What happens if retail requirements change mid-season (packaging, tray layout, compliance)?

We adapt fast.

Because we control lashes, trays, boxes, glue, and kitting in-house, we can update components without disrupting timelines.

If retail requirements change, we revise specs, update compliance documents, and share a clear new timeline.

Q: Do you provide private-label options for multiple SKUs (lashes, glue, kits, variations)?

Yes. We produce full SKU systems under your brand:

Lash styles

Glue

Kits

Multiple box styles

Seasonal packaging

Tray variations

Everything stays under one QC system and one communication line.

You don’t have to coordinate multiple vendors to keep your brand cohesive.

Q: Can you support department-store requirements (barcodes, labeling, packaging specs)?

Yes. We follow US retail standards — barcodes, carton labels, routing guides, packaging formats, and compliance documentation.

If you’re entering retail, we can make your product shelf-ready.

Q: Do you allow sample or small test orders before bulk production?

Yes. We provide production samples and small test runs so you can approve lash quality, packaging, glue, and fit before you commit to bulk.

We never move into full production without your approval — no exceptions.

info@eyelashlabco.com | 213 493 9569

7032 N Figueroa St. Los Angeles CA 90042